Technical instructions are great, whether they’re for putting together an engine or fixing the plumbing under your sink. What’s not ideal is when they start throwing around unfamiliar terminology and expect everyone to know what they mean. For example, suppose they start telling you to use something called a needle valve, and you have no idea what they’re talking about?

Technical instructions are great, whether they’re for putting together an engine or fixing the plumbing under your sink. What’s not ideal is when they start throwing around unfamiliar terminology and expect everyone to know what they mean. For example, suppose they start telling you to use something called a needle valve, and you have no idea what they’re talking about?

Whether you need a quick guide to needle valves for a project you’re working on or merely have a passing curiosity, we want to fill that knowledge gap today. That’s why we’ve put together this guide to all things needle valves — what they are, how they work and some of the different ways they’re commonly used. Armed with information like this, you’ll be ready to go back and tackle that project with a broader picture of the tools being used for the job.

What Is a Needle Valve?

A valve is a device that sits along the line of a pipe or passage and is used to adjust the flow of air or liquid that’s allowed to travel along the passage. For example, perhaps you might turn a handle to shut off the airflow or flip a switch which operates a valve and allows more water to flow through a pipe. Valves such as these are the general operating principle behind things like plumbing, heating and cooling.

A needle valve is a particular type of valve, one which has an unusually small port and a needle-shaped plunger that moves up and down within the confines of the port. In this way, it resembles a needle inside a syringe, which is how it gets its name. The plunger can be moved up and down within the port, allowing for more precise flow control. Some valves only have two settings — open and closed — but a needle valve might be half-open, barely open or fully open creating the opportunity for greater precision.

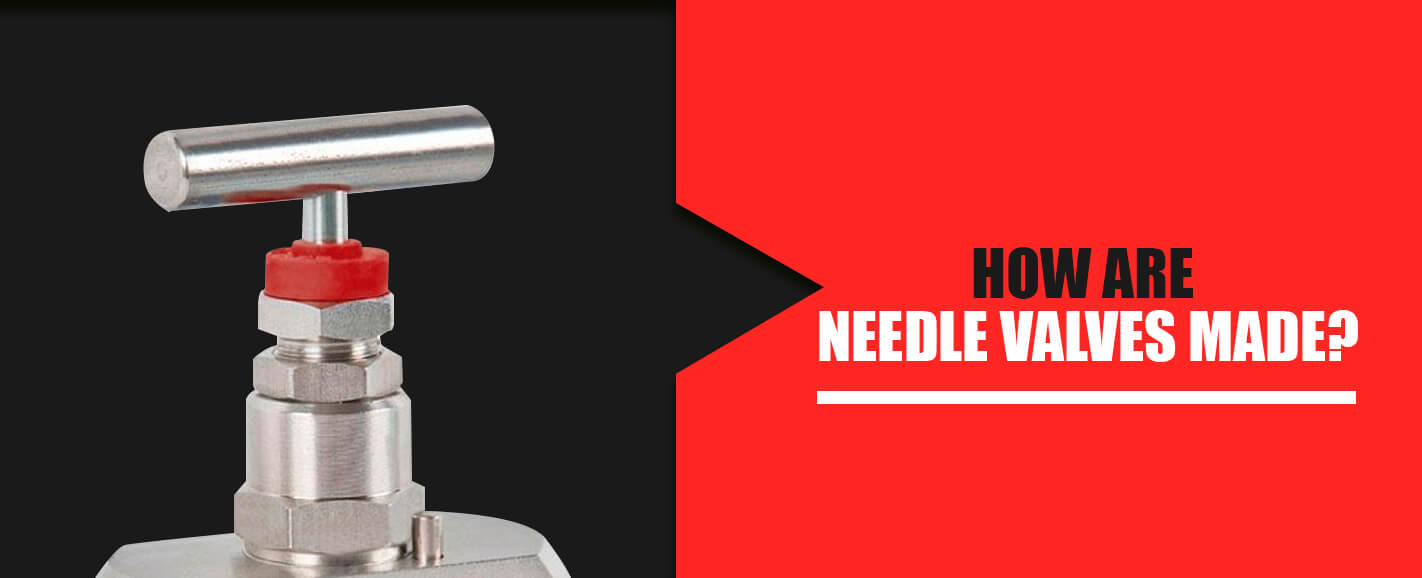

How Are Needle Valves Made?

When it comes to crafting needle valves, it’s essential that they’re built from highly durable material. After all, they’re going to be under a lot of stress as they hold back large amounts of liquid or gas. These liquids or gases may even contain chemicals which can be damaging to many materials. For all of these reasons, it’s imperative that needle valves be constructed from nothing but the best material.

Stainless steel is the most common choice, as this metal is resistant to most forms of chemical damage, corrosion and rust and will last for years without needing to be replaced. It’s also quite low maintenance.

Another critical characteristic of needle valves is they must be able to withstand extreme temperatures. Often, the liquids or gases being pumped through them are either extremely hot or extremely cold. Since both of these can be damaging, special considerations must be taken during construction to ensure needle valves are protected.

Finally, it’s important to note that there is no single uniform construction for needle valves. Different manufacturers build needle valves in different ways because needle valves are used in a variety of settings for a range of applications. This means that different types of needle valves are required, and there must be one for every occasion.

The primary qualifications for a well-constructed needle valve are as follows: they must be durable, sturdy and resistant to chemical and extreme temperature damage. Everything else is a variable that is relative to the job it is being constructed for.

Where Are Needle Valves Used?

As we mentioned, needle valves are commonly used and are particularly useful in small channels and pipes. They’re highly unlikely to be used in a wide tube or passage, simply because the application becomes impractical in this size.

Needle valves are used in any application where precision and exact calibration is of the utmost importance. If a simple “on/off” or estimation is good enough, then a needle valve is not needed. If precise calculations are required, however, and a degree of difference in either direction will truly make a difference, then needle valves are the exact tool for the job.

Because of this, needle valves are used across a wide range of industries. A few of the common ones include:

- Petrochemicals

- Biofuels

- Textiles

- Sugar

- Wastewater treatment

- Food

- Chemicals

- Pharmaceutical

Narrowing the lens still further, needle valves are commonly used in automatic combustion systems and also within engines as part of the carburetor.

How Do Needle Valves Work?

The basic needle valve working principle is that a needle is depressed or withdrawn from a pipe to either restrict or enable the flow of liquid or gas through the tube in question. Let’s take a closer look at how this process works.

The needle valve, while it consists of a whole host of intricate pieces that fit together, functions primarily because of the two major components known as the needle and the seat. The needle is, of course, the conical-shaped plunger that is either depressed into or retracted from the channel to control flow. The seat is a term for the space where the needle enters the channel through which the air or liquid is flowing. In other words, the seat is the space into which the needle enters.

Needles and seats are designed to be exact fits to one another. This means that when the needle is put into place and has been fully depressed, there will be no air gaps at all for any gas or liquid to escape. They are the perfect size, and this is intentional.

At one end, the needle will typically have what looks like a handle. This is a bar which the user can easily grasp, and this piece is known as the stem. If the needle were to be entirely removed, the whole piece would look like the capital letter T. In a needle valve diagram, this will be the primary piece you can see.

At the other end, the needle fits into the seat and is threaded like a screw for ease of operation. For the needle valve to work, the user will rotate the stem, comfortably gripping the handle for ease of rotation. As the needle rotates, the threaded sides turn, and the needle is either lowered or raised out of the seat. Because of the threading, the actual change in needle depth for every turn is extremely minimal. This allows for maximum precision, as the needle can be raised or lowered by the tiniest of degrees.

The savvy thinker may immediately jump to the potential problem of the entire piece becoming too highly pressurized and not being able to handle the buildup of pressure in such a small space once the flow has been cut off. The simple fact is, however, that this piece can work precisely because it is so small. The opening is small compared to the rest of the body of the pipe, meaning that high-pressure is not a problem. On the flip side of this, however, the small opening typically means that these aren’t ideal for high-flow situations.

What Are the Advantages of Needle Valves?

There are nearly countless types of valves out there, and all of them perform the same basic function of regulating the level of flow allowed through a passage. While all of them are the same up to this basic point, however, they diverge from there. Many different valves offer unique sets of advantages and benefits that may make them more suited to certain tasks above others.

Needle valves are no different in this regard. It would certainly be inaccurate to say that a needle valve is the best valve out there, simply because there is no such thing as a “best valve.” Instead, it would be more accurate to say that the needle valve is the best valve for many different particular situations. These would be situations such as those we mentioned earlier, which rely on high levels of precision and accuracy.

To help you determine whether or not a needle valve is the best fit for your intended application, it’s first helpful to know a bit about the specific advantages and disadvantages of needle valves. Let’s look at a list.

Needle Valves: The Pros

- Flexibility: The very simplest of valves only offer two options. Either the flow is open, or it is closed. Needle valves are entirely different in this regard, as they allow you to choose an entire range of midway options. You might set the flow so that it’s very low, but still moving, or almost at the maximum, but not quite. This allows for extreme adaptability. Whatever situation you encounter, you’re likely to be able to adjust the valve to meet it.

- Precision: With a needle valve, precision is always going to be the number one watchword. This is the headline feature that typically leads people to choose this valve over another. Because the needle can be shifted to such minute degrees, users can regulate the flow in exact measurements. This makes the needle valve an excellent choice for settings where exact numbers and measurements are critical.

- Increased efficiency: Because the flow can be controlled so precisely, users can achieve an unprecedented level of efficiency. Rather than allowing far greater flow than necessary and wasting fuel or gas, users can use only the exact amount needed, saving money and energy at the same time.

- High safety levels: As a natural side-effect of the precision and adaptability of these valves, these are some of the safest valves on the market today. Nothing flows through these fittings unless it’s meant to, meaning there is far less chance of leakage, breakage or damage which could lead to dangerous situations.

Needle Valves: The Cons

There aren’t too many downsides to needle valves, but nothing is entirely without drawbacks. Rather than thinking of these as flaws that count against the needle valve, instead, think of them as areas where the needle valve is not quite as strong. Instead, these points may be more the area of expertise of a different valve design.

- Incompatibility with high-flow situations: The opening where the needle fits into the seat is extremely small, not allowing much liquid or gas through at a time even when the opening is entirely unobstructed. Due to this structural reality, a needle valve is not the best choice for high-flow settings.

- Inability to “eyeball it”: Multiple times now, we’ve mentioned how integral precision is to the needle valve’s nature. Every turn of the screw represents the minute raising and lowering of the needle. Because all this is happening within the confines of the seat, however, the user is usually unable to make an educated guess about the needle’s location. Someone using a needle valve would be unable to turn the needle a few places, take a quick look to gauge the result, and then determine that the position was correct. Instead, precision must always be used.

Mako Products’ Needle Valves

Here at Mako Products, we’re proud to be your number one source for Superlok products, and that includes Superlok’s top-of-the-line needle valves.

In these needle valves, each end of the tube is outfitted with the official built-in i-fitting gap gauge to prevent any accidental under- or over-tightening. This includes a colored red ring that pops off when the fitting has been tightened properly, ensuring that the seal is rock-solid every time, with no leaks or safety issues.

In addition to this extra feature, Superlok’s needle valve technology ticks all the boxes you’ve come to expect from a needle valve. They offer precision flow control, high levels of flexibility and adaptability and increased efficiency. Additionally, Superlok’s needle valves are compatible with every other major brand out there, allowing you to use these within your current systems.

Finally, these needle valves are crafted from the most durable stainless steel and can withstand temperatures ranging from negative 65 to 600 degrees Fahrenheit. This makes them a viable choice even for extreme conditions, where other needle valves might not be up to the strain.

Shop Superlok Needle Valve Products Today at Mako Products

Have you made up your mind to purchase your own needle valves today? Then we’d like to invite you to shop our catalog of options here at Mako Products — your number one source for Superlok technology. Enjoy equipment that goes above and beyond doing the job of a simple needle valve. When you choose Mako Products, you’ll also find needle valves equipped with our unbeatable i-fitting technology.

Have you made up your mind to purchase your own needle valves today? Then we’d like to invite you to shop our catalog of options here at Mako Products — your number one source for Superlok technology. Enjoy equipment that goes above and beyond doing the job of a simple needle valve. When you choose Mako Products, you’ll also find needle valves equipped with our unbeatable i-fitting technology.

If you’re ready to begin shopping for needle valves, then we encourage you to learn more about our offerings here at Mako Products. Contact us to learn more about what these products can offer you.