A gap gauge is a great tool to have in your tool belt or back pocket when it comes to many different types of projects. Whether your project involves installing new stainless steel tubing and tube fittings or simply adjusting and repairing existing ones, a gap gauge is an invaluable tool that will help your project be the best it can be.

If you’re not familiar with the handy tool known as the gap gauge, then now is the perfect time to learn about it. To help you familiarize yourself and get more comfortable with this tool, we’ve put together this guide to everything you’ll need to know about gap gauge tools — including the different varieties available, expected costs and how to use them. If you have questions about gap gauges, we’re here to answer them.

Quick Links: What Are Gap Gauges? | Different Types | Cost | How To Use | Fit Guarantees | Pros & Cons | Poor Install Repercussions | Manufacturer Requirements

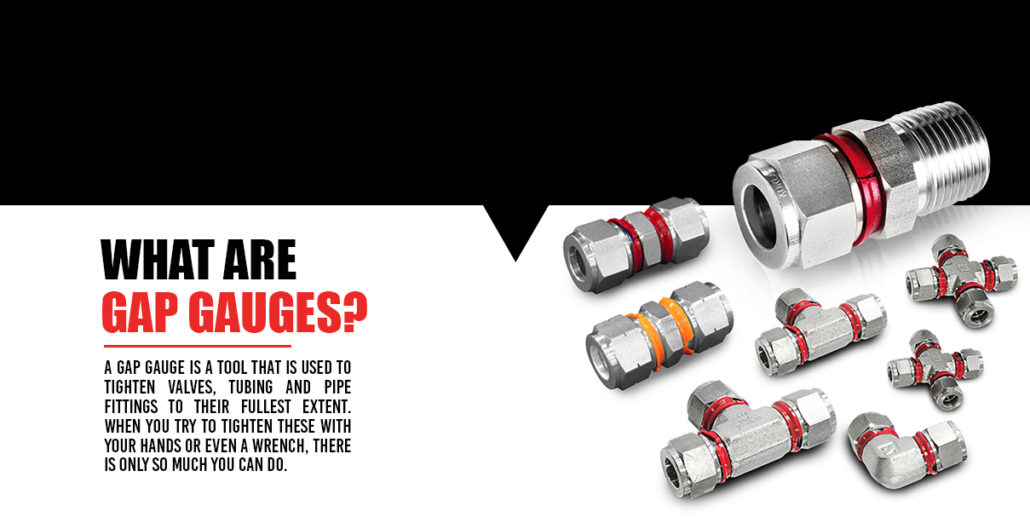

What Are Gap Gauges?

A gap gauge is a tool that is used to tighten valves, tubing and pipe fittings to their fullest extent. When you try to tighten these with your hands or even a wrench, there is only so much you can do. But with the added assistance of a gap gauge, you often tighten these fittings far more effectively.

To do this effectively, gap gauges come in several unique designs, and none of them look like the straight rulers you may be thinking of. Some gap gauges have a roughly circular shape, with a handful of points protruding from each side, something like a star. A gap gauge will also feature a hole in the center of the device, which is placed over the fitting. These points, commonly known as blades or leaves, serve to measure the amount of clearance between two points.

Gap gauges are also used to measure the width between two gaps. Logically, you might wonder what this tool offers that a straight ruler or another measuring device doesn’t. The answer is that these types of gauges are less for measuring inches and more for measuring the possible clearance between two points.

It’s also entirely possible that you may have stumbled across gap gauges before under a different name. You might even hear this tool referred to as a feeler gauge or a gap inspection gauge.

What Are Some of the Different Gap Measuring Tools?

Like many different tools and instruments, there isn’t simply one type of gap measurement gauge designed to work perfectly in every situation. Instead, a variety of devices are available, all based around the same principle but with slightly different designs that make them better suited for unique conditions and settings. The most common types of gap measuring tools include:

- Feeler Gauge: A feeler gauge, while it does mostly the same work as a more traditional gap gauge, looks slightly different in design. This tool consists of many folding leaves of metal, all connected at one central point. These leaves all then collapse together in a nesting format, similar to the ribs of a folding fan. This type of gauge is intended to measure the potential clearance between points, rather than tighten fittings.

- Gap Inspection Gauges: These are some of the most traditional designs you’ll find available — they look like small roughly rectangular shapes with prongs coming off the sides. Some models feature two and three measuring gaps while others feature up to four. Both perform the same task. Additionally, you may also come across gap gauges shaped more like a horseshoe and constructed of metal. These do the same work, even though they look much different.

- Combination Inspection Gauges: These gauges aren’t dedicated tools on their own. Instead, they are built into other tools, can take many different forms and look very different depending on which device they’ve been combined with.

How Much Do Gap Gauges Cost?

Like many things, a gap gauge can cost as little or as much as you’d like, depending on which type of gauge you’re buying and how fancy or well-made the device is. Certainly, you can pick up a cheap plastic tool for a few dollars, and it might break after only a few uses. On the other side of the spectrum, you can spend a lot of money on a much more elegant combined inspection gauge that works as many different tools all at once and will last you a lifetime.

While you can expect a fair amount of variance from one product to another, you can assume a basic gap gauge will likely cost anywhere from $12 to $30. You might find gap gauges that are a little below this estimate or a little above, but if you’re trying to plot out an estimated number for this expense in your budget, this is a relatively safe range to plan for.

How Do You Use a Gap Measurement Gauge During Fitting Installations?

Gap gauges are used to fully tighten fittings. If you’ve ever looked for tips on how to install compression fittings, this gap gauge might be just the tool you’ve been looking for. By fitting the gauge over the end of the fitting in question, you can then rotate your gauge to achieve a much tighter closing than you otherwise could have. The result will be an installation that is connected much more tightly and securely than it would have been otherwise. This, in turn, leads to greater safety and stability. By using your gauge to achieve a tighter and closer fit, you’ll find the result has greater safety and stability all around.

Some gap gauges come equipped with additional visual cues that help you identify when a fitting has been tightened to its fullest extent. This helps ensure that you don’t stop tightening early and, as a result, end up with a leaky or ill-fitted pipe. It also helps you avoid over-tightening a fitting, which can also cause problems.

You can also use many gap gauges to help with your measurements. Let’s say you’re working on repairs and trying to determine how much space you have between one tube fitting and the next, or between the tube joint and the wall. Whatever it is you’re trying to measure, this is where your gap gauge comes into play. You can use this tool to measure the space. You can also use this tool if you’re looking to measure how much of a gap exists between two pieces of material that are supposed to line up with one another.

Do Gap Gauges Guarantee Fit?

No matter how handy a tool is, nothing is infallible, and nothing can guarantee perfect results every single time without fail. While the use of a gap gauge certainly provides a far greater likelihood that your pipe fittings will connect tightly together and perform as intended, many factors are still outside of the gap gauge’s control. Human error could come into play, materials could fail, or the gap gauge itself could fail.

Put simply, a gap gauge is an excellent tool that helps provide greater levels of accuracy at large. However, it is not a cure-all that guarantees perfection in every single case.

What Are the Benefits and Disadvantages of Using a Gap Gauge?

Like any tool, gap gauges come with their own set of pros and cons. Let’s look at a few of these benefits and disadvantages now.

Some of the pros are that:

- They Can Reduce Costs: By using a gap gauge to help you get the job right the first time, you can potentially save yourself additional costs down the road in areas like repairs and maintenance.

- They Improve Installation Quality: By using a gap gauge to get the measurements and fittings installed correctly, you can feel more confident that your work is safe, secure and stable.

- Enhanced Reliability: A gap gauge might not be perfect, but it certainly gets you closer to perfection. Using one of these tools increases the likelihood that your fittings will be reliable and hold up against any strain.

Cons of these tools include:

- Training Is Needed: Gap gauges might not be rocket science, but they also aren’t extremely simple. It takes a little bit of practice to learn how to use these tools correctly, which requires additional time that could otherwise be spent on more active parts of your project.

- Not Everyone Can Use Them: Because training is required to use a gap gauge, not everyone can pick one up and start using it. This can hamper your productivity, as the right person must be available to use the gap gauge, and teams must occasionally shuffle around to make this happen.

- It’s an Additional Cost: Not only is it an additional cost to purchase even one gap gauge, but this isn’t usually where the buying stops. To get the most out of a gap gauge, it should match the brand of the fitting in question. This often means purchasing multiple gap gauges to represent a smattering of different brands.

What Happens If You Install Fittings Wrong?

It’s always a possibility that something will go wrong when you’re installing your fittings, just as it’s possible that anything could go wrong at any stage of any project. The question is, how harmful will it be in this case? Is this a mistake you could easily brush off, or is it one that could have debilitating consequences down the road?

It depends on the exact nature of the error in the fitting installation. It’s possible that the problem is so small it will never be noticed. It’s also possible that the mistake was so large it can destabilize the entire network of fittings and cause severe damage.

The most likely outcome is that your fittings will be less stable than they should be. They will also likely be less safe. If the fittings and tubes aren’t as tight as they should be, it’s possible that gases and liquid will be able to leak out. This type of compression fitting failure could potentially cause safety hazards to those nearby.

The issues present due to incorrect fitting installations might not be immediately apparent. It could be that initially, everything seems fine. You might not even notice the problem until you perform a tube fitting installation inspection later. Perhaps it isn’t until weeks or months later that you see you have a compression valve leak, a wobble or a structural insecurity. Maybe there’s an easy fix that allows you to rectify these errors quickly — or maybe fixing the problems requires a long and invasive process that costs you a lot of extra money.

By the same token, using a gap gauge doesn’t guarantee your job will be done correctly every single time. However, that’s no reason not to use any aid or tool that has the potential to reduce risk and error alike. By using devices like this, you’re taking steps to ensure a project that’s free from errors or misaligned fittings while also increasing the safety levels of your tube fittings.

Do All Manufacturers Require Fitting Installation Tools?

A gap gauge is an excellent tool to keep with you as you work on installations, fittings and repairs. It helps give you an extra level of peace of mind when it comes to installing your fittings, as you can more confident that the work you’re doing is secure, stable and completely tightened.

The question of whether or not they’re necessary is a difficult question to answer. Technically, there are few tools out there that are 100 percent necessary 100 percent of the time. However, many of these tools that aren’t strictly “necessary” are still extremely valuable. While it might be possible to do the job without them, you would be much more stressed, much less confident of your success and much more susceptible to failure.

Rather than asking whether this is a tool you need, think of the gap gauge as a handy tool you should own. Will you use it every day? Maybe, maybe not. But no matter how often you use it, this is the type of tool that is always valuable to have in your back pocket. The next time you find yourself performing a tube fitting installation, you may be glad you have it. Store it with the rest of your fitting installation tools until you need it, and you’ll be happy you did.

Buying a gap gauge is your choice. Think of the average tool kit. Maybe you frequently use a few screwdrivers, the hammer and the level. But you still hang onto the rest of the tools, even if you don’t use them as often. Why? Because you know that at some point, the odds are good that you’ll be glad you have them.

Contact Mako Products for More Information About Superlok Fittings

Wouldn’t it be fantastic if instead of having to worry about your designated gap gauge, your fittings tightened themselves? That way, you wouldn’t have to worry about buying multiple gap gauges to fit each brand, training workers to use gap gauges or forgetting to carry these tools around with you.

This is exactly what you’ll get when you shop at Mako Products — your U.S. source of Superlok fittings and technology. Superlok is the brand you need with the i-Fitting technology, an integrated and patented red ring that eliminates the need for a gap gauge. Once you have properly tightened your fitting, the red ring pops off to reveal a blue visual inspection ring. You’ll have visual confirmation that the fitting is tightened to spec when the red ring snaps off to show the blue underneath.

These Superlok products aren’t just about achieving higher levels of safety, although they certainly achieve this. They’re beneficial because anyone can use them without extensive training. They’re also quick, reliable and save you both time and money. If you’re going to be working with fittings, this is a feature you won’t want to miss out on.

Learn more about our i-Fitting technology today and how it can make your repairs and installations simpler, easier and less stressful for you. Please don’t hesitate to contact us to request more information or to learn more about how our technology can work for you.